Abstract: Chengdu Baosteel can-making water reuse project, constructed by Shanghai Winner Environmental Technologies Co., Ltd., adopts advanced pretreatment + membrane process, and the quality of produced water meets the requirements of production water and landscape water. It has achieved good economic and social benefits, and has become a demonstration project of water reuse in the can-making industry.

Fig. 1 Produced Water of Water reuse system for fish farming

I. Customer Profile

Chengdu Baosteel Can Co., Ltd. is a can-making enterprise of Baowu Group, located in Xindu District, Chengdu City, mainly engaged in the manufacturing and research and development of beverage cans, and is one of the leading enterprises in the can-making industry in Southwest China.

Fig. 2 Chengdu Baosteel Gate

The company mainly serves customers of famous brands at home and abroad, such as carbonated drinks, beer and tea drinks, with an annual output of 1.6 billion cans.

Fig.3 Can production workshop

II. Project Background

In the production process of the can, it is necessary to clean the coolant attached to the surface of the metal forming process by adding acid cleaning agent, and the resulting sewage will be discharged to the standard after treatment.

According to the general requirements of green production of Baowu Group, it is necessary to build a reclaimed water reuse system on the basis of the original sewage treatment system, so as to realize the goal of wastewater resource utilization and bring economic and social benefits.

The client compared technical solutions for water reuse system, from the waste water recycling, water reuse water quality standards and processing costs, eventually Shanghai Winner was entrusted to wastewater reuse system design, supply, construction, commissioning of Chengdu Baosteel Can Co., LTD., and after the project put into production is responsible for the operation management of the system.

III. Project Implementation Process

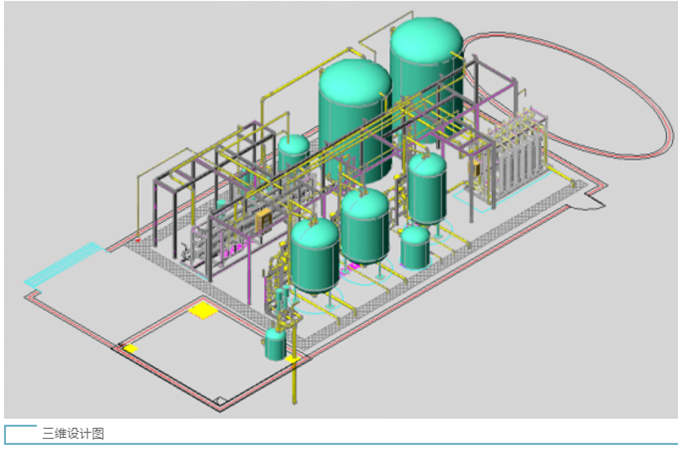

As demonstrated by Shanghai Winner Technical Team, this project adopts advanced and reliable pretreatment + membrane process to ensure that the system can meet the water quality and quantity requirements of the client.

The implementation phase of the project includes design, equipment procurement, civil construction, mechanical and electrical installation, trial operation and production operation.

This project used three-dimensional software to design, in order to improve the drawing expression effect, ensure the accuracy of material statistics, and speed up the later construction progress.

According to the site conditions of the client, the system has been rationalized layout, in order to meet the function at the same time to achieve beautiful appearance.

Fig. 4 3D design drawing

Fig. 5 Panorama of the wastewater reuse workshop

The project started construction at the end of 2017, began trial operation in the third quarter of 2018, and officially put into operation in 2019.

IV. Project Achievements

After preliminary construction and later optimization, the project is now in stable operation. The quality of the produced water is superior to the local tap water standard. As production water and landscape water, it has been well received by the client and has become a demonstration project of wastewater reuse in the can-making industry.

Fig. 6 Landscape Fish Pond